The Algorithm driven supply chain decision-making platform empowers the resilience of the supply chain. In combination with VX's nationwide warehousing and distribution services - the interchange between the "digital world" and the "physical world", the platform aims to solve the core business problems of enterprises and support the business growth of enterprises at the optimal cost. The core team is formed by members from top universities, such as Stanford, Cornell, Peking University, Tsinghua University, Fudan University and Shanghai Jiao Tong University, we adopt AI+OR algorithms to drive digital and intelligent decision-making processes of enterprises, reducing costs and increasing efficiency of supply chain.

Why Choose Integrated Supply Chain Services?

In the face of the ever-changing market environment, does the existing supply chain become a bottleneck for enterprises? Under the guidance of establishing a resilient supply chain, VX drives efficient operation services with the top-level design of the digital and intelligent supply chain, bringing a full value upgrade to you.

VX's integrated supply chain service is an optimal strategic partner accompanying the business growth of enterprises

Insights

Exploring real business pain points while reducing costs and increasing efficiency for core business modules.

Agility

Quickly responding to complex changes in the market by applying OR and AI algorithms.

Pragmatism

Engaging in implementation by leveraging the warehousing and distribution capabilities to realize the actual implementation of the scheme.

Cases of Integrated Supply Chain Service

Supply Chain Optimization Brain

The self-developed supply chain optimization platform helps enterprises gain

insight into risks and optimize decision-making process to respond to

changes in the ever-changing market environment.

5%

Order fulfillment rate improvement20%

Fulfillment time improvement5-15%

Cost reduction

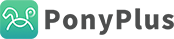

A supply chain network planning product

As an optimization algorithm product based on mixed integer programming, Hetu is committed to providing enterprises with supply chain optimization decisions. The digital-twin technology is used to simulate the baseline, find out the bottleneck, and confirm the optimization direction. Based on this, multiple scenarios are built and compared to select the optimal plan. In addition, Hetu's rich component library can support custom KPI dashboards to help enterprises finalize customized supply chain planning solutions.

the supply chain

multiple scenarios

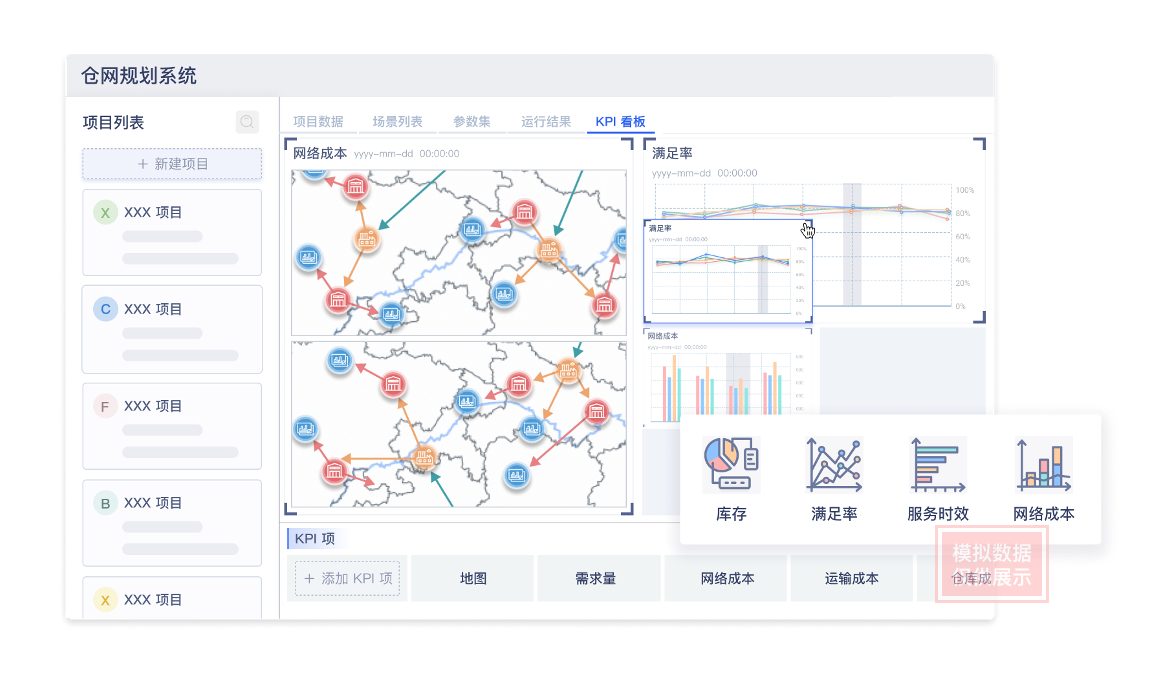

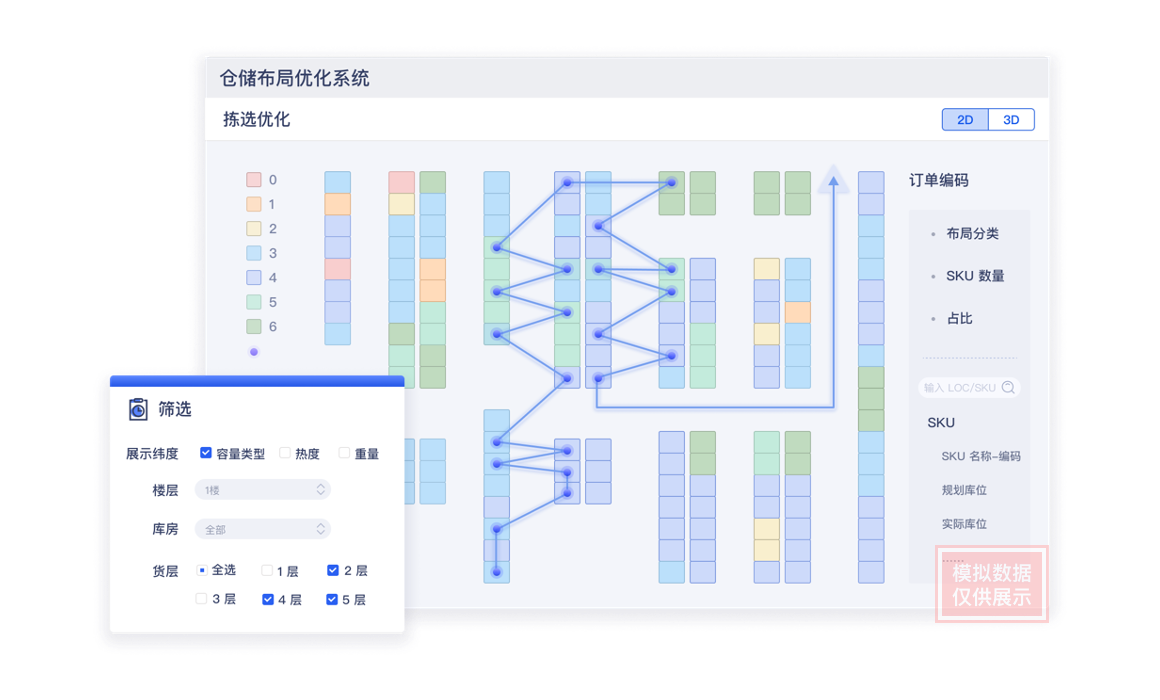

A warehousing optimization product

Based on popularity and relevance of the product, Shuidi formulates quantitative indicators for the warehousing efficiency, dynamically adjusts the layout and picking path of products in the warehouse, which achieves targeted matching of people, goods and yards, and greatly improves the operational efficiency.

layout

scheduling

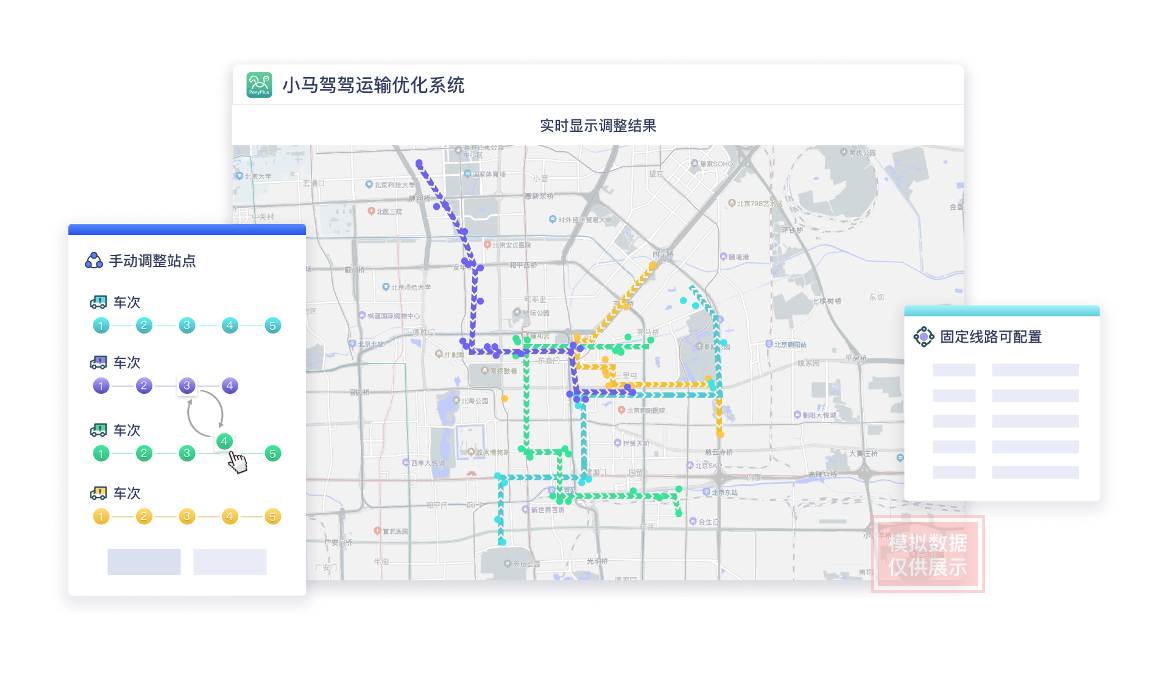

A transportation optimization product

PonyPlus dynamically optimize parths and vehicles for scientific scheduling in consideration with factors such as the number of store orders, time windows, loading capacity of vehicles, and provides services for distribution task allocation and distribution route planning, so as to help enterprises save transportation vehicles, transportation mileage, scheduling time, vehicle costs, and achieve cost reduction and efficiency increase.

JGWAB NO. 31011202012968

JGWAB NO. 31011202012968